限扭 The torque limiter

生产制造标准紧固件销、键;非标精密圆柱类、异型柱键类、英制精(粗)钢键条;异型键类零件,传动胀套、限扭产品;高压水泵;机械加工服务的专业企业。

关键词:键丨销丨高压水泵

所属分类:

产品描述

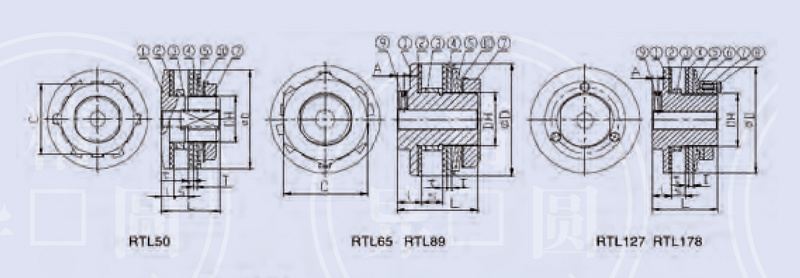

零件名称Parts:

1、主体Hub

2、摩擦片Friction Plate

3、称环Lining Ring

4、压板 Pressure Plate

5、蝶形弹簧 Disc Spring

6、导向压板 Pilot Plate

7、调节螺母 Adjusting Nut

8、调节螺栓 Adjusting Bolt

9、锁紧螺钉 Locking Screw

10、止退垫片 Gaskot

旋转角度和扭矩设定 Set the Rotation Angle and Torque

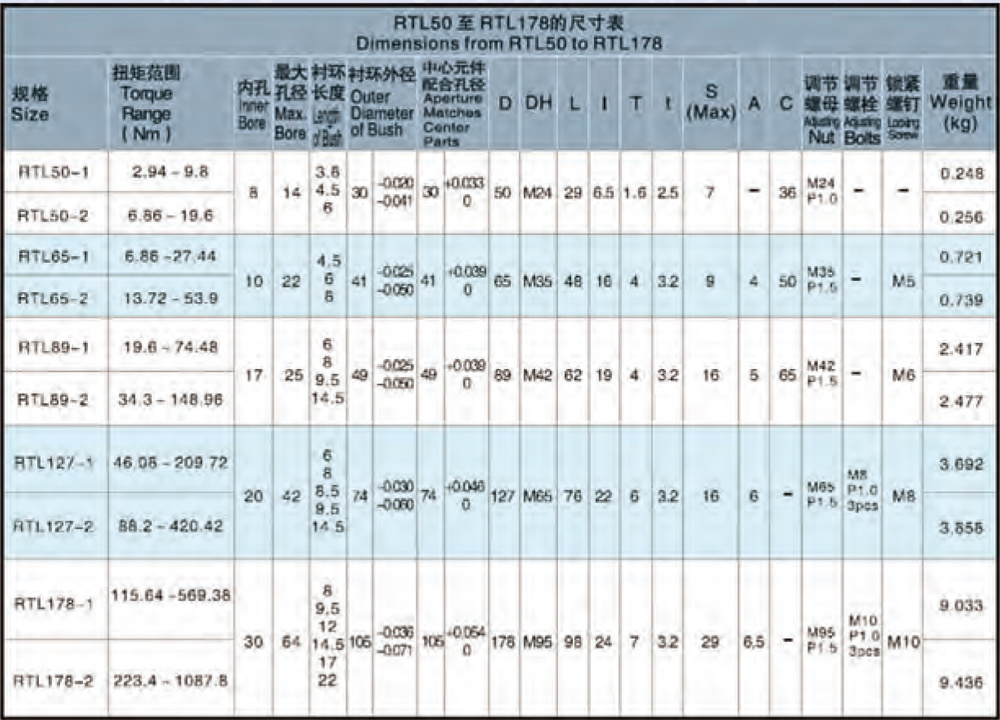

选型SELECTION

1.依据负载条件或设备本身的力的大小来决定所需打滑扭矩。如果设备负载条件不清楚,请将打滑扭矩设为马达产

生在承载限扭装置的轴上扭矩的1.5-2倍。

2.选用限扭装置时,应选择有足够大的扭矩范围和孔径范围。

3.根据两个摩擦片中间夹的中心元件的厚度来决定选择最合适的衬环宽度。

The required sliding torque is set depends upon the loading or the force of the equipment. If the loading conditions are not clear, please set the sliding to que as 1.5-2 times of one upon the shaft that carries the Torque Limiter. Please select the Torque Limiter with sufficient torque and aperture ranges.

Select optimum lining ring length according to the center part thickness clamped between the two friction discs.

扭矩的设定TORQUESETTING

限扭装置扭矩的设定是依靠上紧和松开调节螺栓和/或调节螺母来实现的。针对RTL50到RTL89,依靠调节螺母;针对RTL127和RTL178,依靠调节螺栓。

Tight and loose the adjusting bolts and/or nuts to set the torque of the Torque Limiter. The Limiter form size RTL50 to RTL89 depend upon the adjusting nuts, whereas RTL127 and RTL178 depends upon the adjusting bolts.

扭矩的设定可以在将限扭装置安装在轴上后进行,过程是:

Set the torque after mounting the Limiter upon the shaft as follow:

RTL50到RTL89的规格

For sizes form RTL50 to RTL89

首先,用手旋转上紧调节螺母,以至固定碟型弹簧和压板;

Rotate to tight the adjusting nuts by hands to fix the disc spring and plate;

然后,试着用扳手将螺母上紧,约60度。

Then, try to tight the nuts (about 60℃)by wrench

RTL127到RTL178的规格

ForsizesformRTL127toRTL178

首先,旋转螺母,固定碟型弹簧和压板,再上紧每一个调节螺栓,约60度。

First, rotate the nuts to tight the disc spring and pressure plate. Then tight all the adjusting bolts (about 60℃)

然后,如果限扭装置在正常负载条件下能够打滑,请逐渐上紧螺母(RTL50到RTL89)或螺栓(RTL127到RTL178),直到限扭装置停止打滑。请务必保证均匀上紧(或松开)每个螺栓。

If the Limiter slides with normal loading,please tight the nuts (for sizes form RTL50 to RTL89) or bolts (form RTL127 to RTL178) generally until the Limiters stop sliding. Please ensure that each bolt is tightened or lossened averagely.

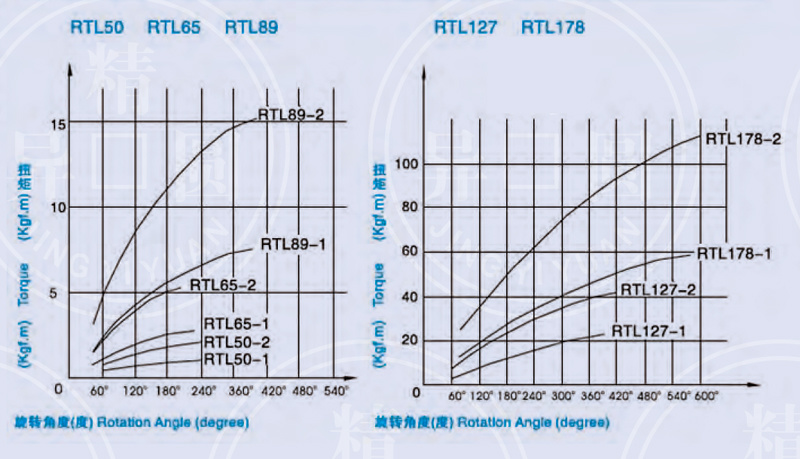

通过这样的几次测试,来找到适合设备的限扭设定。下表显示有效旋转角度和限设定的关系,供参考。

Find out the setting torque appropriate for the equipments after tests. Please refer the following Table that shows

the relationship between the effective rotation angle and torque setting.

为了精确扭矩设定,推荐试运行一次限扭装置,比如,在当转速50-60rpm,500转时,旋转调节螺母货螺栓45度。

To make torque setting precisely, we recommend you to use Torque Limiter for trial once. For example, while the rotation speed is 50-60 rpm with 500 circles, rotate the adjusting nuts or bolts around 45℃

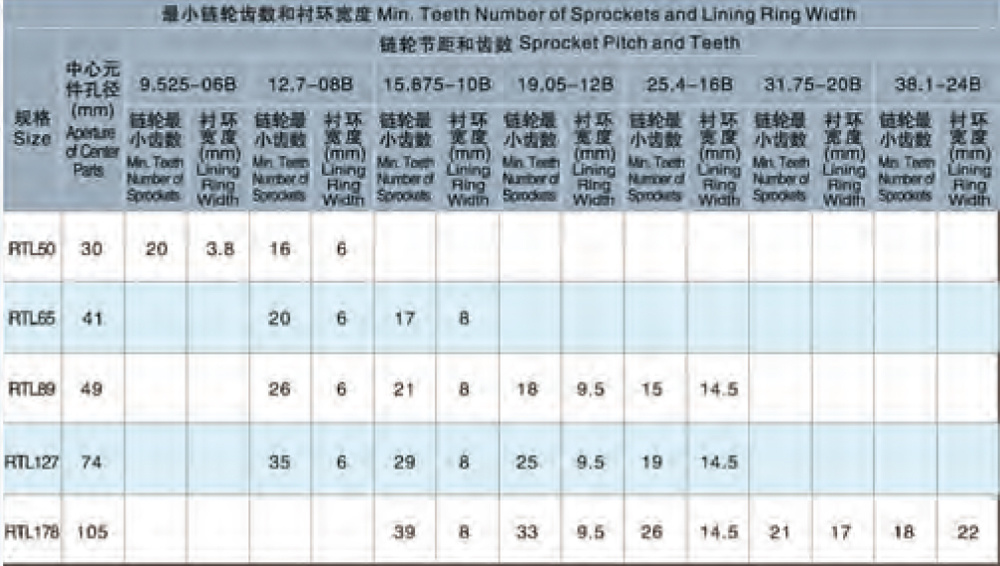

CENTERPARTS中心元件

1.中心原件的摩擦表面应加工,以保证额定转矩,以及平面度、平行度、与孔一致和防锈、防油污。推荐表面粗糙度为Ra1.6。如果中心元件不能满足以上技术要求,打滑扭矩将不稳定。

2.请按下表来加工中心元件的孔,和选择最小链轮齿数和衬环宽度。

Process the friction face of center parts to ensure the rated torque, planeness and parallelism in line with the bore and protect the parts from the rust and oil. The recommended surface roughness(Ra) is 1.6. The sliding torque will be not stable if the center part is defected.

Please process the bore of center parts according to the following Table and, select sprocket with min. teeth number and lining ring length.

生产制造标准紧固件销、键;非标精密圆柱类、异型柱键类、英制精(粗)钢键条;异型键类零件,传动胀套、限扭产品;高压水泵;机械加工服务的专业企业。其中:销、键两大系列13个品种数千个型号和规格,并承接用户特殊要求的非标件及不锈钢销、键类等产品的定制生产。生产已有四十年的历史。现有员工70人,其中工程技术人员和各类专业管理人员15人,占全体员工总数的21%。企业占地面积8000平方米,建筑面积4000平方米。企业生产能力3000万件。产品按照国际标准进行生产,企业通过了ISO9001:2000版质量管理体系认证。

欢迎您留言咨询